Subsea Pipeline Inspection

Comprehensive Subsea Pipeline Inspection Solutions

SUBSEA PIPELINE INSPECTION

Safeguarding Safety,

Efficiency & Compliance

SUBSEA PIPELINE INSPECTION

Safeguarding Safety,

Efficiency & Compliance

The Importance of Subsea Pipeline Repair

Ensuring Operational Continuity

Preserving Safety & Environmental Protection

Damage in the pipelines can pose safety hazards to personnel and marine life, as well as result in environmental pollution. Subsea pipeline inspection and maintenance, however, help mitigate these risks, safeguarding workers and the marine ecosystem.

Extending Pipeline Lifespan

Over time, subsea pipelines may deteriorate due to factors such as corrosion, fatigue, or external impacts. However, by conducting subsea pipeline inspection maintenance, operators can address these issues and extend the operational lifespan of the pipelines.

Regulatory Compliance

Pipeline operators must adhere to stringent regulations and industry standards. Regular inspections and prompt repairs are essential to comply with regulatory requirements related to safety, environmental protection, and integrity management.

Subsea Pipeline Inspection – FAQ

The pipeline repair process involves several steps to address any damages or integrity issues within the pipeline. These steps typically include:

- Damage assessment

- Isolation and depressurisation

- Pipeline excavation

- Pipeline repair

- Testing and verification

Throughout the entire process, safety protocols, regulatory compliance, and industry best practices are strictly followed to ensure the quality and integrity of the repaired pipeline.

Common methods used for stabilising subsea pipelines include rock dumping, gravity anchors, rock bolts, and trenching. These methods help reinforce the pipelines’ stability and reliability in challenging subsea environments.

Get In Touch

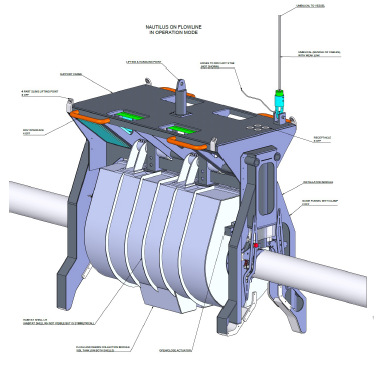

Introducing NAUTILUS

- Working Depth: 150 m

- Pipeline Repair Diameter: 12” to 16”

- Wrapping Material: Composite material (NRI Viperskin)

- Max. Temperature: 92°C

- Max. Pressure: 90 Bar (subject to the number of wrappings)

- Remote-controlled robot for pipeline inspection and repair.

- Featuring PAUT/TOFD capabilities for overcoating and 3LPP.

- Pipeline coating removal services.

- Pipeline repair options, including patching and wrapping ROV support for necessary prep work such as trenching.